Introduction

In today’s world, 3D printing is becoming an integral part of innovation and technological advancement. From prototyping and customizing parts to developing complex architectural forms, 3D printing offers unique opportunities to turn creative and engineering ideas into reality. To achieve impressive results, careful attention to 3D printing setups and techniques is essential, alongside creativity. This article provides an in-depth overview of the best 3D printing tips for high-quality printed products.

Choosing the Right Material: Finding the Perfect Raw Material for Your Project

3D printing offers a wide variety of materials, each with unique properties. From plastic and resin to metals, selecting the right material is crucial for 3D printing success. Understanding the characteristics of each material and matching them to your project’s specific requirements ensures the right choice for success.

An Overview of Different Materials for 3D Printing

- Plastic: PLA and ABS are popular for their affordability and versatility.

- Resin: Ideal for high-detail objects with smooth surfaces.

- Metal: Used for technical applications requiring durability and high-temperature resistance.

Tips for Choosing a Material Depending on the Type of Project

- Prototyping: Plastic materials like PLA are suitable for testing functionality.

- Decorative Objects: Resins provide high detail and smooth surfaces for decorative elements.

- Engineering Solutions: Metallic materials offer high strength and heat resistance.

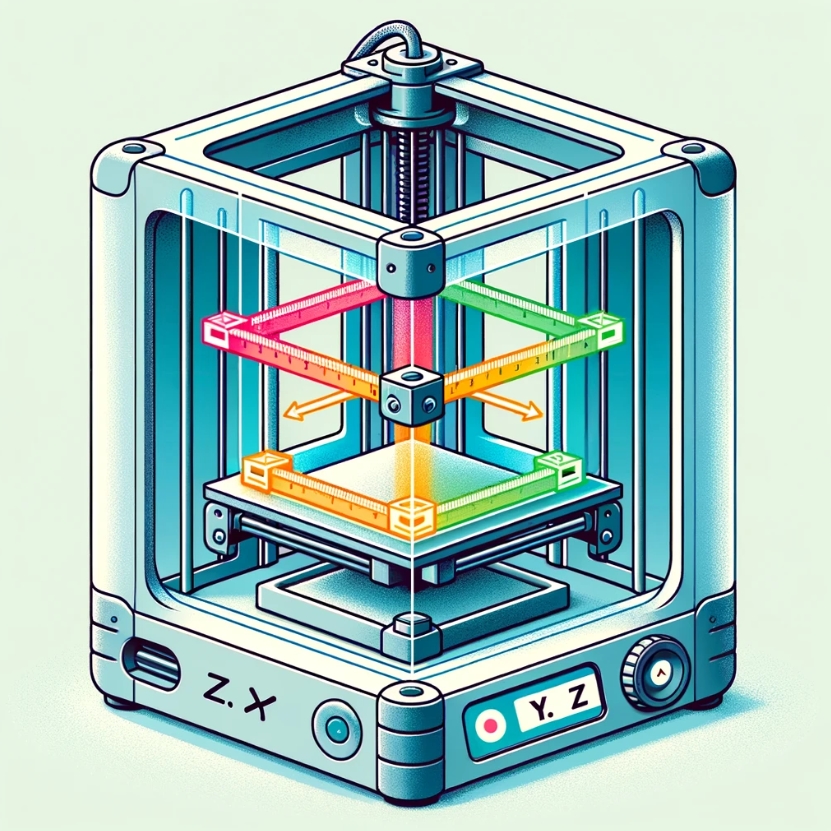

Printer Calibration: The Secret to Precision in Every Millimeter

Precise printer calibration is crucial to prevent potential problems with the size and shape of printed objects. Adjusting the X, Y, and Z axes ensures high levels of accuracy and quality.

The Value of Accurate Calibration

- Distortion Prevention: Ensures accurate movement to prevent distortion and warping.

- Dimensional Compliance: Ensures accurate object dimensions, crucial for technical projects.

- Improved Print Quality: Precise calibration improves overall print quality.

Adjusting Temperature and Print Speed: Harmony of Heat and Motion

Proper temperature and print speed settings are key to the quality and consistency of 3D printing. Understanding the characteristics of each material and adjusting settings accordingly is crucial.

| Material | Optimal Printing Temperature (°C) |

| PLA | 190-220 |

| ABS | 220-250 |

| Resins | 20-30 |

| Stainless Steel | 220-260 |

| Titanium | 300 and above |

The Importance of Proper Print Speed

- Minimizing Errors and Deformations: Proper speed helps avoid problems.

- Improved Layer Adhesion: Moderate speed promotes better adhesion.

- Saving Time: Optimal speed is crucial for efficiency.

Using the Right Support and Fill Layer: The Basics of Support for Outstanding Results

The balance of support and fill layer is crucial in 3D printing. The support layer prevents warping of overhanging parts, while the fill determines the internal cavity strength.

Tips for Selecting the Best Parameters for Each Project

- Object Type: Parts with protruding elements require careful support.

- Material: Plastic generally requires less filling than metals, while resins may need more careful support layer adjustment.

- Strength Requirements: Prototypes may use minimal filling, while functional parts require denser fill for stability.

3D Model Preparation: In Search of the Perfect Shape

Preparing a 3D model before printing is crucial. Using specialized editing and model preparation software, like MeshLab and Blender, ensures model cleanliness and integrity, reducing errors and inconsistencies during printing.

Tips for Preparing Models

- Error Checking: Use tools to find and correct errors in models.

- Optimize Geometry: Avoid overly complex geometry to simplify printing.

Level of Detail Control: The Fine Line Between Beauty and Efficiency

Managing the level of detail is crucial in 3D printing. Adjusting layer size and print speed can enhance detail while maintaining project feasibility.

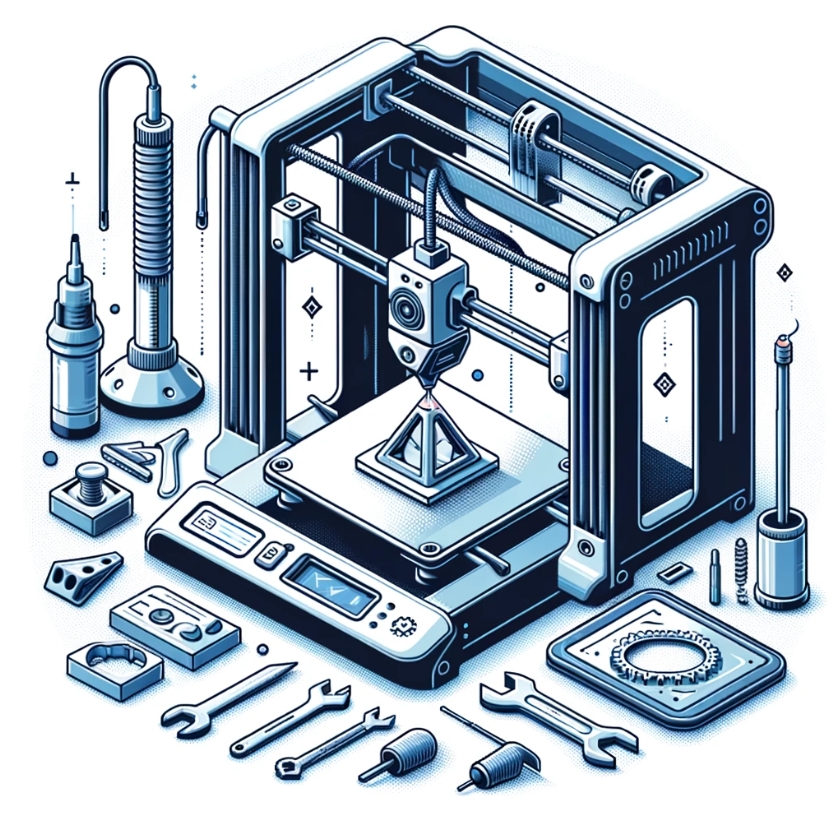

Printer Maintenance and Care: The Key to Long and Trouble-Free Operation

Regular maintenance, including nozzle cleaning and part inspection, is essential for the longevity and efficiency of your printer. Proper material selection and preparation prevent nozzle clogging and other technical problems.

Experimentation and Optimization: The Path to Excellence through Creativity

Experimentation with different settings and optimization techniques, including the use of test prints, is key to achieving outstanding results in 3D printing.

Conclusion: Turning Technique into Art

Applying these comprehensive tips together is key to achieving the best results in 3D printing. Continuous learning and mastery of new techniques are essential in this dynamic field. Creativity, innovation, and continuous development are the keys to success.

Helen’s passion is 3D Technology. She always loved hi-tech but 3D Reality was something that she never thought of before. She attended the first course on 3D printing technology and she was immediately fascinated by it.