Table of Contents

Introduction

Metrology’s Crucial Role in Industry

In today’s rapidly advancing technological landscape, precise measurements are pivotal for the success of diverse industries. Metrology, the science of measurement, establishes standards and methods crucial for accurate determination of physical quantities. It serves as the backbone across sectors, ensuring accuracy and reliability in measurements, from manufacturing to scientific endeavors.

Significance of 3D Scanning in Modern Technology

Over the past decades, 3D scanning has emerged as a revolutionary measurement technology, enabling the creation of highly accurate three-dimensional models. Widely used in engineering, medicine, design, and more, 3D scanning not only provides precise data but also visually represents objects, enhancing analysis and decision-making processes. This technology has become integral, fostering innovation and efficiency across industries.

Fundamentals of 3D Scanning

Operational Mechanism of 3D Scanning

3D scanning employs various technologies, such as laser scanning, stereophotogrammetry, and tomography, to collect precise three-dimensional data about objects. Laser scanning, for instance, measures distances using laser light, generating a point cloud of data that forms a detailed computerized representation of the object.

Applications Across Industries

3D scanning finds applications in engineering, medicine, architecture, and beyond. It aids in creating accurate prototypes, planning surgeries through 3D organ images, and modeling buildings. Measurement accuracy is paramount in fields like manufacturing and medical diagnostics, where 3D scanning ensures precision down to millimeters.

Importance of Accuracy in 3D Scanning

The accuracy of 3D scanning, referring to its ability to faithfully reproduce an object’s geometry, is pivotal. This precision is particularly critical in fields like parts manufacturing and medical diagnostics, influencing the reliability of data generated by the scans.

Role of Metrology in 3D Scanning

Necessity of Accurate Measurements in 3D Space

In 3D scanning, accurate measurements in three-dimensional space are imperative. Precision in measurements impacts an object’s final representation and its utility across various fields, from engineering to medicine.

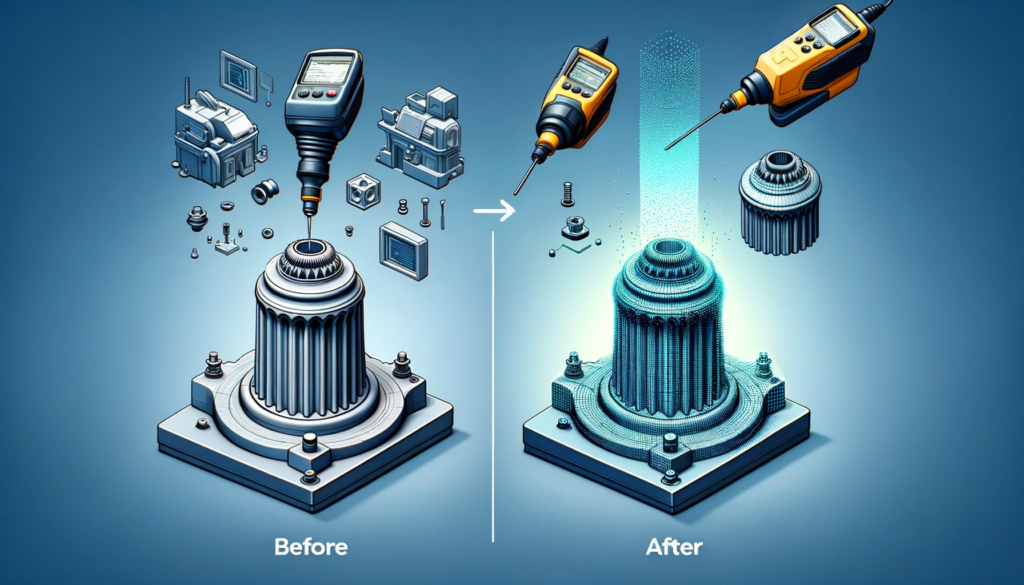

Metrology’s Impact on Measurement Quality

Metrology ensures the high quality and reliability of 3D measurements by establishing standards and methods. It eliminates potential data distortions, correcting errors, and providing a foundation for standardization and consistency in 3D measurements.

Advantages of Metrology Approach in 3D Scanning

Adopting a metrology approach brings multiple benefits, including high measurement accuracy, standardized processes, and increased confidence in results. It facilitates innovation, improving product quality and manufacturing processes.

Metrology Kit in 3D Scanning

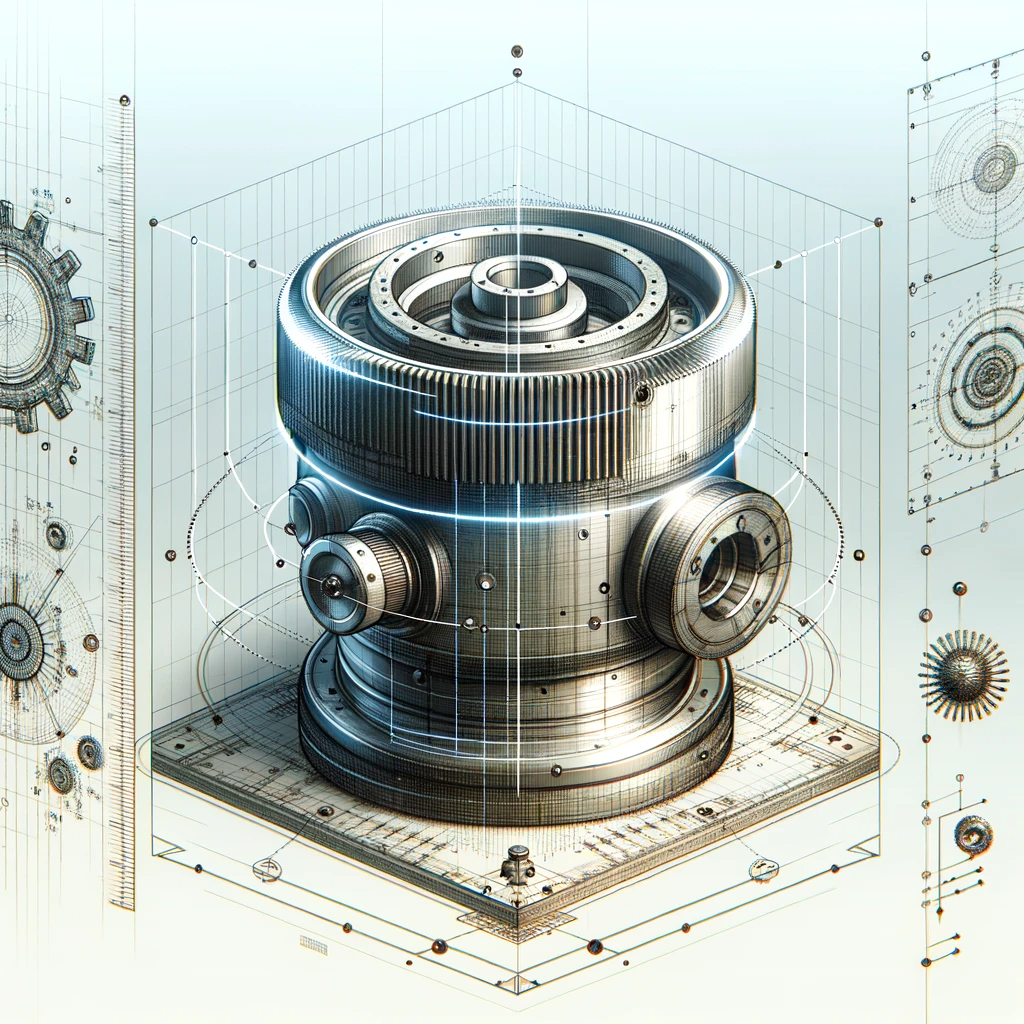

Definition and Components

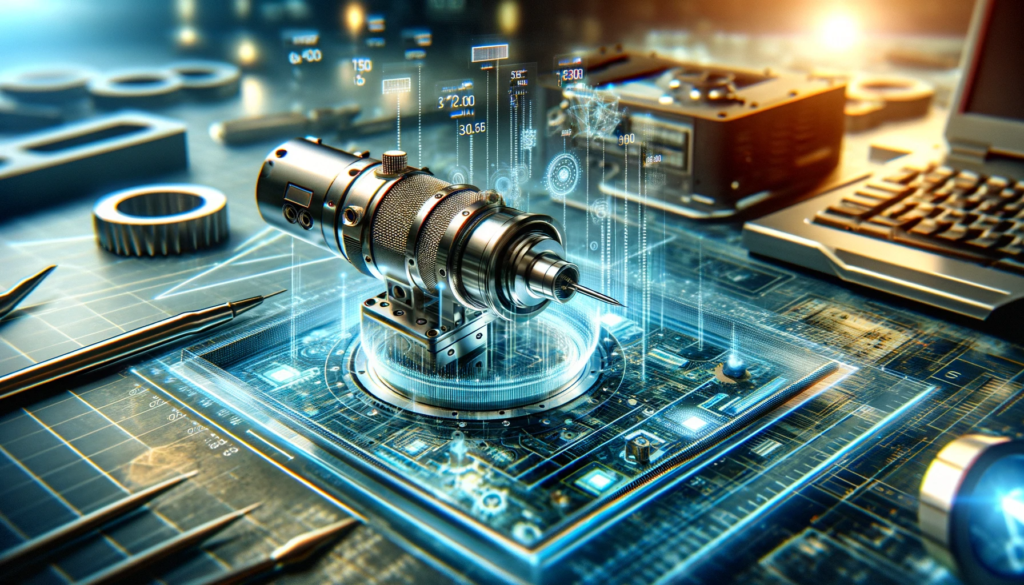

The Metrology Kit in 3D scanning comprises tools ensuring high accuracy, standardization, and reliability in three-dimensional measurements. Key components include laser scanners, data processing software, precise positioning systems, calibration standards, and temperature compensators.

Examples of Included Tools

The Metrology Kit encompasses tools like photogrammetric cameras, contact measurement systems (e.g., Coordinate Measuring Machines), interferometric sensors, and inertial navigation systems, forming a comprehensive set for precise 3D measurements.

Applications Across Industries

Usage in Production Processes

In production processes, the Metrology Kit ensures accuracy and quality control for manufactured parts. Laser scanners and coordinate measuring machines play crucial roles in checking size, shape, and geometry, especially in industries like automotive and mechanical engineering.

Role in Medical 3D Printing

In medical 3D printing, the Metrology Kit is indispensable for creating precise and customized medical implants. Accurate measurements enable the development of tailored objects, ensuring high standards of quality and safety.

Applications in Aviation and Automotive Industry

The Metrology Kit is vital in the aviation and automotive sectors, supporting quality control and safety measures. Laser scanners and coordinate measuring machines verify critical part dimensions, ensuring compliance with technical standards.

Benefits and Challenges

Advantages of Metrology Kit Usage

- High Accuracy and Reliability: Ensures precise geometric data.

- Process Standardization: Facilitates comparison between different systems.

- Increased Efficiency: Reduces rejects, enhancing product quality.

- Innovation Opportunities: Enables advanced product creation.

Challenges in Implementing Metrology Approaches

- High Cost of Equipment: Precision tools can be expensive.

- Need for Specialized Skills: Requires trained personnel.

- Environmental Challenges: Temperature changes can affect accuracy.

- Complex Implementation: Integration into production processes demands time and effort.

Despite challenges, the benefits outweigh, contributing to efficiency and innovation in various industries.

Future of Metrology Kit in 3D Scanning

Emerging Trends and Developments

- Advances in Sensor Technology: More sensitive lasers and sensors for accurate and faster measurements.

- Integration with AI: Automation of data analysis, pattern identification, and error correction.

- Enhancements in Photogrammetry: More accurate and affordable image-based analysis.

Expected Improvements and Innovations

- Miniaturization and Portability: Development of compact, portable devices for field use.

- Integration with Cloud Technology: Storage and processing of large data sets for flexibility.

- Interoperability with Other Technologies: Tighter integration with 3D printing, virtual reality, and augmented reality.

- Development of Standards: Creation and improvement of 3D scanning standards for uniform requirements.

These developments will contribute to more accurate and efficient 3D measurements.

Conclusion

Significance of Metrology Kit in 3D Scanning

In conclusion, the Metrology Kit in 3D scanning is essential for high-precision measurements in three-dimensional space. From engineering to medicine, this toolkit ensures accuracy and reliability, laying the groundwork for innovation and efficiency.

Future Prospects

The future holds promise with advancements in sensor technology, AI integration, and interoperability with other technologies. Miniaturization, integration with the cloud, and the development of standards will further contribute to the evolution of 3D scanning applications across industries. The Metrology Kit will continue to be a driving force in technological progress, influencing industries, medicine, and science.