Introduction

In the ever-evolving landscape of modern industry, one technological marvel stands out — Resin 3D Printing. This groundbreaking method has reshaped manufacturing, offering a deep dive into precision, innovation, and versatility. Let’s explore the principles, advantages, and diverse applications of Resin 3D Printing.

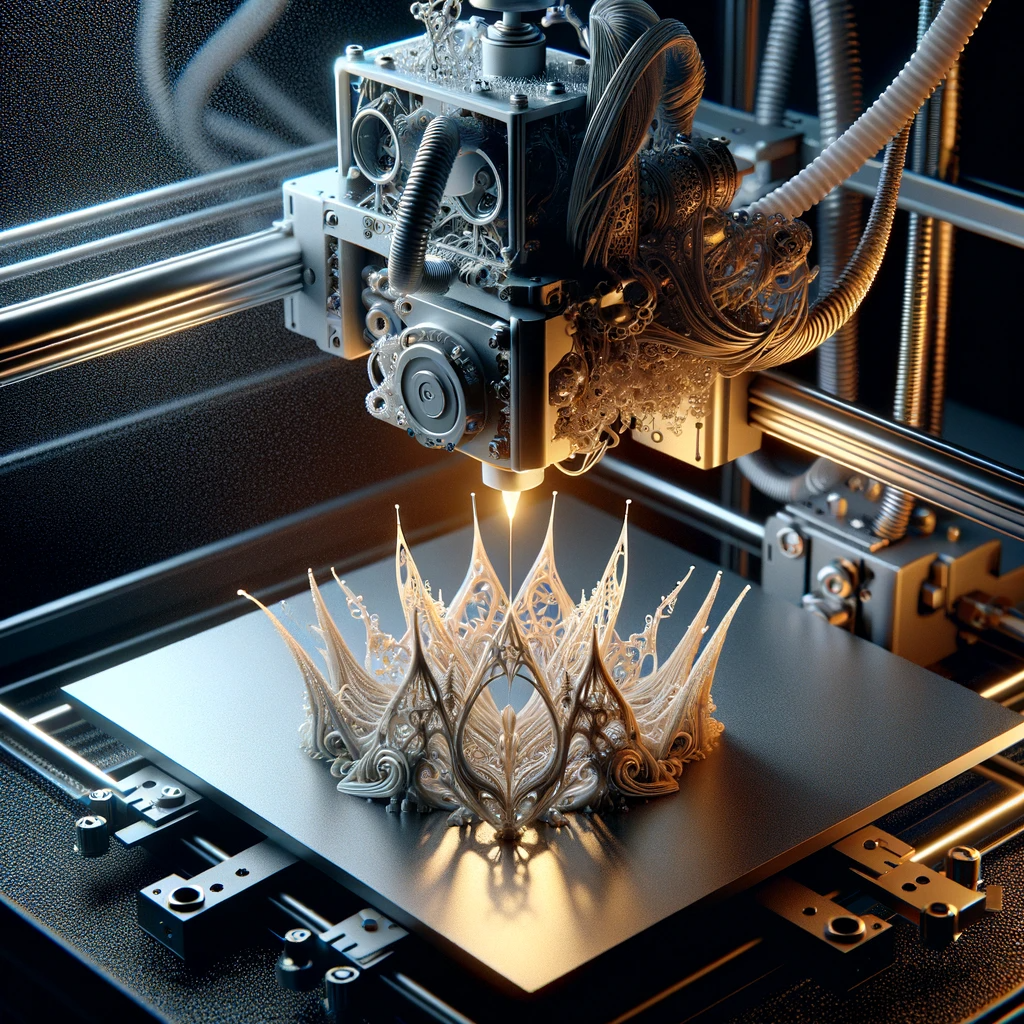

Principle of Resin 3D Printing

At its core, Resin 3D Printing harnesses the power of resin polymerization under ultraviolet light. This process transforms liquid resin into a robust material with unparalleled precision. The controlled exposure to UV light makes Resin 3D Printing the go-to choice for crafting intricate and accurate parts.

Benefits of Resin 3D Printing

Why does Resin 3D Printing stand out? The answer lies in its high precision, enabling the creation of fine structures and complex geometries. The flexibility to choose from various resins caters to specific project needs, from prototyping to final product functionality.

Applications Across Industries

Resin 3D Printing has revolutionized diverse industries. In medicine, it crafts customized implants with anatomical precision. Aviation benefits from lightweight yet robust parts, enhancing aircraft efficiency. The design realm embraces the technology for high-precision prototypes, opening avenues for unparalleled creativity.

Comparing Technologies

Pitting Resin 3D Printing against Fused Deposition Modeling (FDM) highlights strengths and considerations. Resin excels in accuracy, while FDM offers economical advantages. The key lies in balancing the precision of Resin 3D Printing with the cost-effectiveness of FDM for optimal manufacturing.

Materials for Resin 3D Printing

The array of available resins empowers manufacturers to tailor projects precisely. From transparent resins for clarity to durable options for functional parts, material selection shapes the final product. The future promises even more specialized resins, expanding possibilities.

Trends and Future Outlook

Resin 3D Printing’s trajectory is poised for acceleration. Trends point to faster printing, a broader resin selection, and heightened accuracy. The future holds promise for increased accessibility, unlocking new potentials in manufacturing, medicine, and the arts.

Project Showcase

Real-world success stories abound. In medicine, Resin 3D Printing creates custom implants; in aviation, it enhances aircraft performance. Artists leverage the technology for unique sculptures, foreshadowing a future filled with innovation.

Equipment Selection Recommendations

Choosing the right equipment is pivotal. Accuracy, resolution, print speed, and resin compatibility are key considerations. Safety and maintenance ease also factor in. Thoroughly researching and consulting expert reviews ensures the chosen equipment aligns with specific needs.

Conclusion

Resin 3D Printing is the driving force behind innovation in modern manufacturing. Its precision, material diversity, and widespread applications make it a cornerstone in various industries. As we navigate the future, Resin 3D Printing will lead us towards personalized, precise, and sustainable manufacturing, shaping the way we create and innovate.

Helen’s passion is 3D Technology. She always loved hi-tech but 3D Reality was something that she never thought of before. She attended the first course on 3D printing technology and she was immediately fascinated by it.